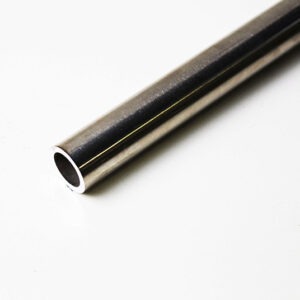

4130 TUBING

4130 TUBING

TW’s cold drawn seamless chromoly 4130 tubing is a lighter weight, higher strength alternative to carbon steel. As the market leader in seamless 4130 tubing, TW Metals delivers a full range of rounds, squares, rectangles, and streamline products. Our tubing is manufactured to Mil-T-6736B, AMS-T-6736, ASTM A519, and AMS 6360 specifications.

The 4130 Chromoly Advantage

4130 Chromoly is a low-carbon alloyed steel with heightened amounts of chromium and molybdenum. The added chromium helps to increase the material’s hardenability and corrosion resistance, whereas the molybdenum helps increase its toughness and temperature resilience.

As a result, the material is suitable for applications subjected to challenging conditions or elemental exposure. Also called AISI 4130, Alloy Steel Grade 4130, and Chrome Moly Alloy, it offers a variety of other performance characteristics.

- Strong Creep Strength

- Excellent Strength-To-Weight Ratio

- Improved Rigidity

- High Tensile Strength, Ductility, And Toughness

- Robust Wear Resistance

- Easy To Fabricate

- Good Impact Resistance

- Lighter Than Other Carbon Steels

4130 Chromoly is easily hardened by heat treating or work hardening. It can be case-hardened using carburizing. When annealed, it exhibits good formability, machinability, and weldability.

COMMON 4130 CHROMOLOY STEEL USES

The strength, durability, and affordability combination makes AISI 4130 steel tubing perfect for various applications. Examples include:

- Original Equipment Manufacture, Or OEM, Parts

- Rock-Crushing Equipment

- Roll Cages

- Aerospace Components

- Drill Bits

- Automobile Parts

- Bicycle Frames

- Milling And Cutting Tools

- Gears

- Motorcycle Frames

- Agricultural Machinery

| Typical Chemical Properties | |

| Carbon Max | 0.33 |

| Manganese Max | 0.60 |

| Phosphorous Max | 0.025 |

| Sulfur Max | 0.025 |

| Silicon Max | 0.35 |

| Chromium Range | 0.80-1.10 |

| Molybdenum Range | 0.15-.25 |

| Typical Mechanical Properties | |

| Tensile Strength Min | 90,000 psi |

| Yield Strength Min | 80,000 psi |

| Elongation Min | 10% |

| Hardness Min | 95 HRB |

TW Metals offer as wide range of stock sizes and processing capabilities for your company’s 4130 tubing needs. We stock .1875” OD – 5” OD with wall thicknesses .028” thru .625” wall.

YOUR FULL-SERVICE 4130 CHROMOLY TUBING PROVIDER

TW Metals is an ISO 9001:2015-certified seamless 4130 Chromoly tubing supplier. We carry round, square, and rectangular shapes in many sizes and lengths.

Our team is happy to assist if you need Grade 4130 tubing but aren’t sure which type is optimal. With years of experience supplying specialty metals for critical applications, they can help you make the right choice.

Comprehensive Chromoly Services

TW Metals strives to make 4130 Chromoly tubing acquisition simple. We offer a full suite of value-added services designed to optimize supply chains, enabling you to focus on your business.

- Abrasive Sawing

- Lathe Cutting

- Band Saw Cutting

- Laser Cutting

- Forming

- Machining

- Painting

- Tube Assemblies

- Bending

Ensuring Your Get Flawless Material

TW Metals stands behind the products we supply. Material is acquired from trustworthy mills, and compliance is verified upon arrival. Precision equipment is used to ensure our products meet applicable requirements.

Some projects have elevated quality requirements, and we welcome the challenge. Nondestructive examination, or NDE, can be performed upon request to check for imperfections.

- X-Ray

- Ultrasonic Testing