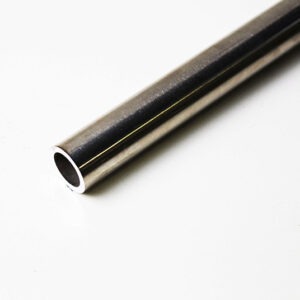

C276 NICKEL PIPE

C276 NICKEL PIPE

Alloy C276 nickel pipe is made from a nickel-molybdenum-chromium alloy with addition of tungsten having excellent corrosion resistance in a wide range of severe environments. The high molybdenum content makes this alloy especially resistant to pitting and crevice corrosion. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures.

Typical applications: pollution control, chemical processing, pulp and paper production, and waste treatment.

STOCK SIZE RANGE:

OD: .250″ – 4″

Wall: Schedule 10 – Schedule 80

Specifications

Welded: ASME SB619/ ASTM B619, ASME SB626/ ASTM B626

Seamless: ASME SB622/ASTM B622, ASTM B983

| Nickel nominal | 57 |

| Chromium | 14.5-16.5 |

| Iron | 4.0-7.0 |

| Molybdenum | 15.0-17.0 |

| Cobalt | .5-2.5 |

| Sulfur | 0.03 |

| Tungsten | 3.0-4.5 |

| Cobalt | 2.5 |

| Carbon | 0.01 |

| Manganese | 1.0 |

| Silicon | 0.08 |

| Phosphorous | 0.04 |

| Vanadium | 0.35 |

| Annealed | Mpa | |

| Yield Strength (0.2% offset) ksi min | 41 | 283 |

| Tensile Strength ksi min | 100 | 690 |

| Elongation % | 40 |