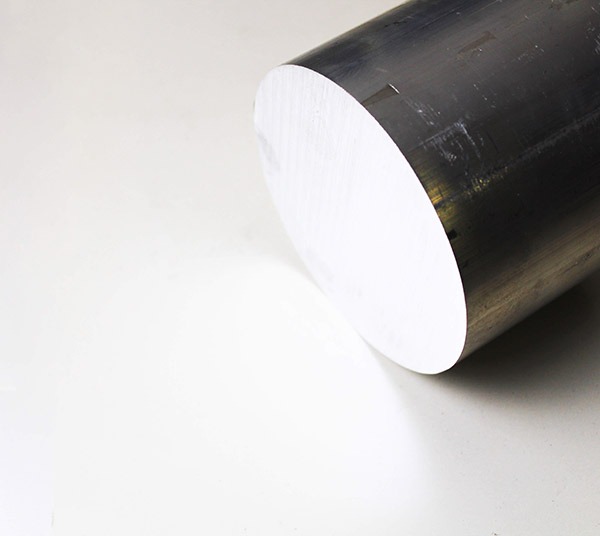

9310 ALLOY BAR

9310 ALLOY BAR

9310 is low alloy steel containing nickel, chromium and molybdenum. It has high core hardness and high fatigue strength. This alloy is best machined in the normalized and tempered state. All of this makes 9310 excellent for aircraft parts.

APPLICATIONS OF 9310 ALLOY:

- Heavy-Duty Gears

- Clutch Parts

- Machined Components

- Aircraft Parts

Typical Chemical Properties

| Minimum Properties | Tensile Strength , psi | 187,000 |

| Yield Strength, psi | 162,000 | |

| Elongation | 15% | |

| Hardness | bhn 229 | |

| Chemistry | Carbon( C) | 0.07- 0.13% |

| Chrome (Cr) | 1.00-1.40% | |

| Manganese (Mn) | 0.40- 0.70% | |

| Molybdenum (Mo) | 0.08- 0.15% | |

| Nickel ( Ni) | 3.0- 3.50% | |

| Phosphorus (P) | 0.025% | |

| Sulphur (S) | 0.025% | |

| Silicon (Si) | 0.15- 0.35% | |

| Copper ( Cu) | 0.35% |