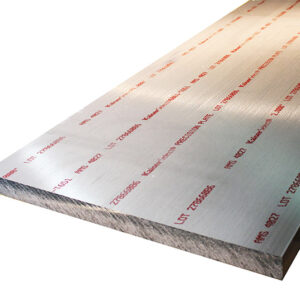

7075 ALUMINUM SHEET

7075 ALUMINUM SHEET

Alloy 7075 aluminum coil and sheet have been and remain the baseline standard with a good balance of properties required for aerospace applications. 7075 aluminum is among the highest strength alloys available and used in highly stressed parts. Corrosion resistance and machinability are rated as fair, though the addition of chromium provides good stress-corrosion cracking resistance in 7075 aluminum sheet products. As with alloy 2024, alloy 7075 is available in bare form or in clad (“Alclad”) to offer even further protection from corrosion.

7075 ALUMINUM APPLICATIONS

- Aircraft and aerospace structures

- Alclad skin sheet

| Silicon | 0.4 |

| Iron | 0.5 |

| Copper | 1.2-2.0 |

| Manganese | 0.3 |

| Magnesium | 2.1-2.9 |

| Chromium | 0.18-0.28 |

| Zinc | 5.1-6.1 |

| Titanium | 0.2 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum | |

| Temper | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| KSI | KSI | % | |

| O (annealed) | 40 | 21 | 9-10 |

| T6 | 74-78 | 63-69 | 5-8 |

TW Metals stocks a full product line ranging in thicknesses from .016 – .190 and in widths of 48″ and 60″. All are certified to ASTM B209 and both Bare and Alclad are certified to the appropriate AMS-QQ-A and AMS specifications.