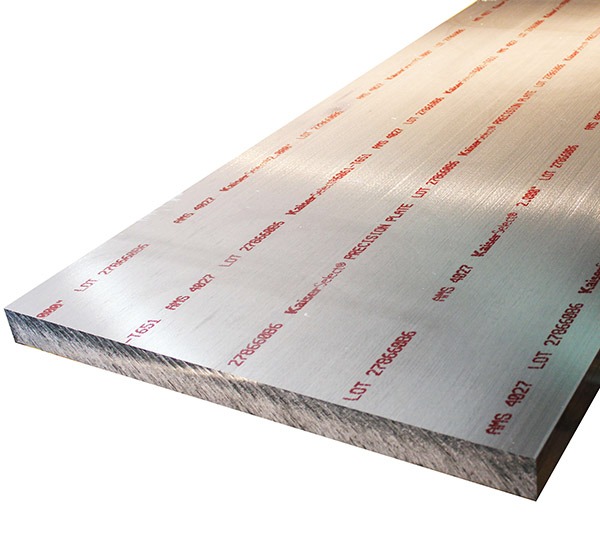

7050 ALUMINUM PLATE

7050 ALUMINUM PLATE

7050 ALUMINUM PLATE

Alloy 7050 aluminum plates are the principal choice for aerospace applications, especially in the 3-6 inch thickness range. It exhibits better toughness/corrosion resistance characteristics than the older, more established alloy 7075. Since it is less quench sensitive than most other aerospace alloys, this alloy maintains its strength properties in thicker sections while retaining good stress corrosion cracking resistance and fracture toughness levels. AMS 4050 is commonly associated with 7050, though various manufacturers require their own specifications.

APPLICATIONS:

- Fuselage frames

- Bulkheads

Chemical Composition Limits (WT %)

| Silicon | 0.12 |

| Iron | 0.15 |

| Copper | 2.0-2.6 |

| Manganese | 0.1 |

| Magnesium | 1.9-2.6 |

| Chromium | 0.04 |

| Zinc | 5.7-6.7 |

| Titanium | 0.06 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum |

Typical Mechanical Properties

| Thickness | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| In. | KSI | KSI | % |

| .250-6.00 | 83-73 | 73-63 | 13-11 |

Aluminum Alloy 7050 plate is available in two tempers: T7451 (formerly T73651) offers better stress corrosion cracking resistance and excellent exfoliation resistance at slightly lower strength levels; and T7651 combines the highest strength with good exfoliation corrosion resistance and average stress corrosion cracking resistance.