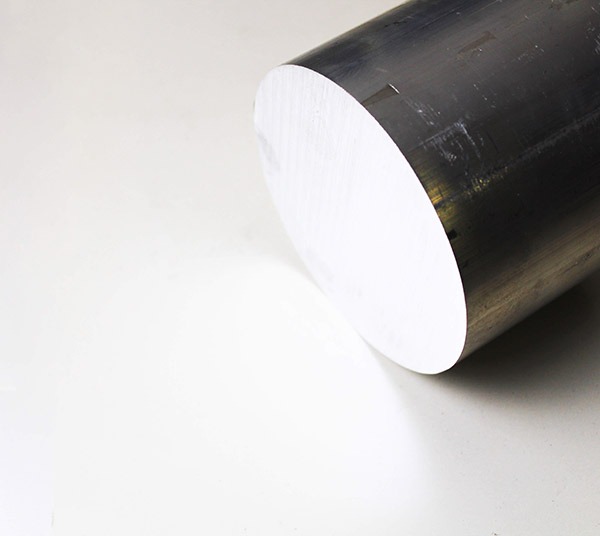

6063 ALUMINUM BAR

6063 ALUMINUM BAR

6063 (UNS A96063) is an aluminum bar that offers good extrudability and high quality surface. This alloy is used for standard architectural shapes, custom solids and heatsinks. Also used for electrical applications in T5, T52 & T6 due to its electrical conductivity.

6063 is commonly referred to as an architectural alloy. It has a high resistance to corrosion with excellent finishing characteristics. 6063 has average machinability and forming hot or cold is acceptable. Also due to its conductivity it is utilized in electrical substations. Commonly used in the manufacture of pipe railings, furniture, windows, stair rails, and in pipe railing.

Available shapes: Flats

Tempers: T5, T52, T6

Specifications: ASTM B221, AMS 4156, AMS QQ-A-200/9

Typical Chemical Composition %

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | 0.20 | 0.45 | ||||||||

| Maximum | 0.60 | 0.35 | 0.10 | 0.10 | 0.90 | 0.10 | 0.10 | 0.10 | 0.05 | 0.15 |

Remainder Aluminum

Typical Mechanical Properties

| Temper | Tensile | Hardness | ||||

|---|---|---|---|---|---|---|

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T5, T52 | 27 | 186 | 21 | 145 | 12 | 60 |

| T6 | 35 | 241 | 31 | 214 | 12 | 73 |