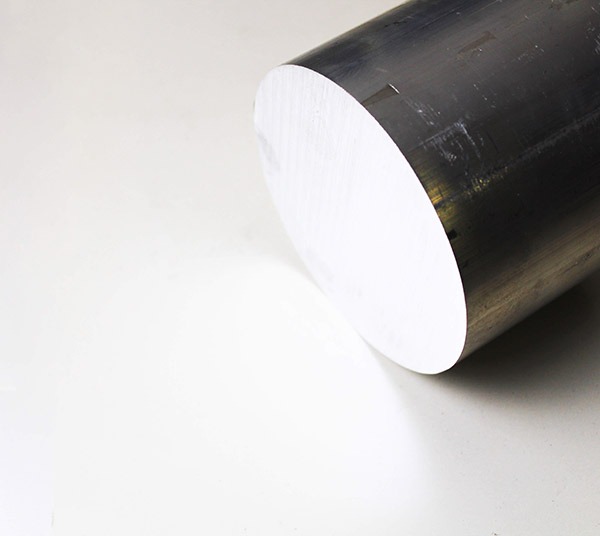

6061 ALUMINUM BAR

6061 ALUMINUM BAR

6061 (UNS A96061) is an aluminum bar with cold finished or extruded aluminum wrought product with excellent corrosion resistance, good workability, fabulous joining characteristics and adequate machinability.

6061 is one of the most widely used heat treatable aluminum alloys. It has excellent corrosion resistance, good workability, fabulous joining characteristics, and adequate machinability. Stamping, bending, and deep drawing are easily accomplished. Commonly used in marine and truck components, railroad cars, pipelines, and furniture. We stock 6061-T6, 6061-T651, and 6061-T6511.

Available shapes: Flats, squares and rounds

Tempers: T6, T651, T6511

Specifications: ASTM B211, AMS 4115, AMS 4116, AMS 4117, AMS 4128, AMS-QQ-A-225/8 & ASTM B221, AMS4150, AMS 4160, AMS 4161, AMS-QQ-A-200/8

Typical Chemical Composition %

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | 0.40 | 0.15 | 0.80 | 0.04 | ||||||

| Maximum | 0.80 | 0.70 | 0.40 | 0.15 | 1.20 | 0.35 | 0.25 | 0.15 | 0.05 | 0.15 |

Remainder Aluminum

Typical Mechanical Properties

| Temper | Tensile | Hardness | ||||

|---|---|---|---|---|---|---|

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T6, T651 | 45 | 310 | 21 | 145 | 25 | 65 |