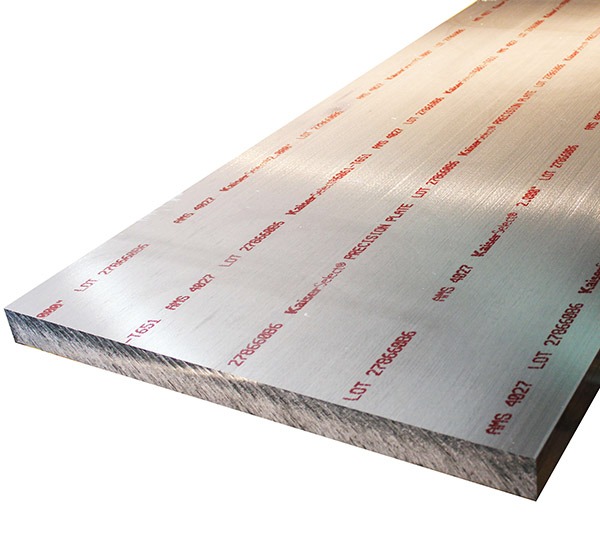

6013 ALUMINUM SHEET

6013 ALUMINUM SHEET

Alloy 6013 aluminum coil and aluminum sheet is a new medium strength aerospace alloy that provides improved formability, lower density and corrosion resistance. The T4 condition allows 6013 aluminum to be formed and demonstrates better stretch forming characteristics. The part can then be aged to the T6 condition without costly heat treating or annealing operations. The yield strength is 12% higher than Alclad 2024 and resistant to exfoliation and stress corrosion cracking.

6013 ALUMINUM APPLICATIONS

- Fuselage panels

- Engine cowlings

- Leading and trailing edges

| Silicon | 0.6-1.0 |

| Iron | 0.5 |

| Copper | 0.6-1.1 |

| Manganese | 0.2-0.8 |

| Magnesium | 0.8-1.2 |

| Chromium | 0.1 |

| Zinc | 0.25 |

| Titanium | 0.1 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum | |

| Temper | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| KSI | KSI | % | |

| T6 | 52 | 46 | 8 |

TW Metals has availability in sheet thicknesses from .018 – .150 in standard widths. All material is certified to AMS 4347.