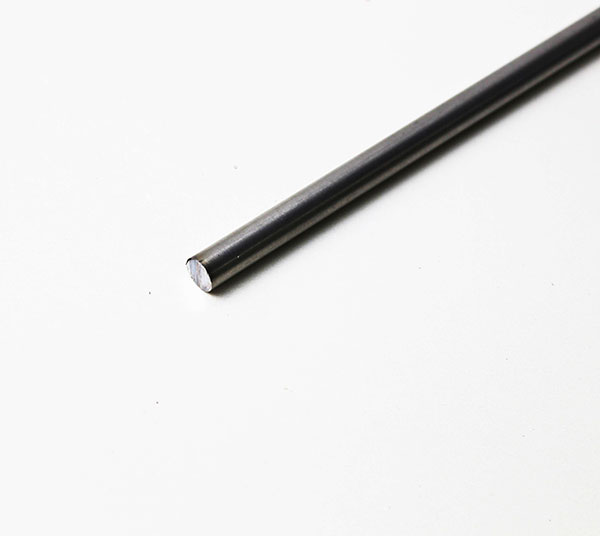

600 NICKEL BAR

Bar:

- ½” up to 4”

Specifications:

- UNS: NO6600

- W. Nr./EN: 2.4816

- AMS: 5540

- ASME: B 168

- ASTM: SB 168

- Federal or Military: QQ-N-281

Chemical Composition, %:

|

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Al |

Ti |

B |

P |

S |

|

| MIN |

72.0 |

14.0 |

6.0 |

0.05 |

– |

– |

– |

– |

– |

– |

– |

– |

| MAX |

– |

17.0 |

10.0 |

1.50 |

1.0 |

0.5 |

0.5 |

0.3 |

0.3 |

0.006 |

0.015 |

0.015 |

Features

- Exhibits superior oxidation resistance at high temperatures

- Excellent resistance to nitrogen, hydrogen and carbiurization

- Can be used in air as well as other environments continuously for long periods of time

- Hot working is relatively easy

Applications

- Nuclear power plants

- Industrial chemical evaporators

- Heat treatment furnace parts

- Vacuum furnace fixtures

- Chemical and food processing equipment

- Vinly chloride monomer production

- Catalyst regenerators on petrochemical production

- Heat exchangers

- Industrial acid and alkali equipments

- Afterburner parts and other components used at high temperatures

- Paper mill and alkaline digesters

- Thermo couple sheathing in aggressive atmospheres

Corrosion Resistance

The composition of Nickel 600 provides corrosion resistance in a wide range of corrosive environments. The addition of chromium provides superior corrosion resistance in acidic environments, compared to a pure nickel, while allowing the material to maintain corrosion resistance in a reducing state and exhibit superior corrosion resistance to alkaline solutions. Nickel Alloy 600 is also highly resistance to stress-corrosion cracking.