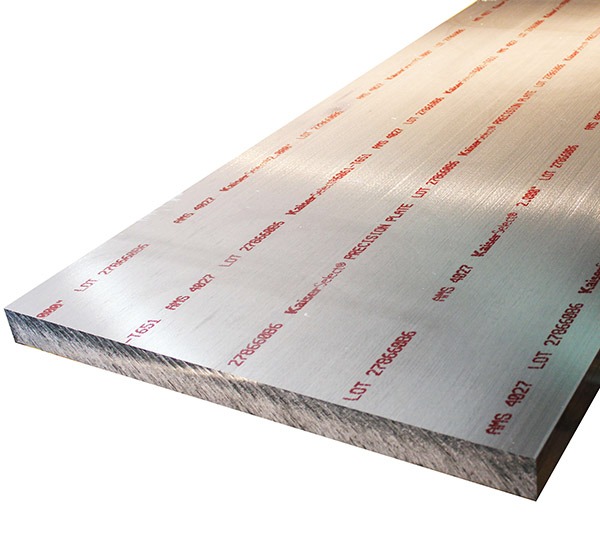

5086 ALUMINUM PLATE

5086 ALUMINUM PLATE

Alloy 5086 aluminum plates have even higher strength than 5052 or 5083 and its mechanical properties vary significantly with hardening and temperature. It is not strengthened by heat treatment; instead, it becomes stronger due to strain hardening or cold working of the material. This alloy can be readily welded, retaining most of its mechanical strength. The good results with welding and good corrosion properties in seawater make Alloy 5086 extremely popular in marine applications.

Available is a wide range from .250″ – 2.00″ in widths up to 120″ and lengths up to 300″ and certified to ASTM B928.

APPLICATIONS:

- Shipyard

- Tank cars

- Welded and superstructures

- Patrol and work boat hulls

- Armor plate

Chemical Composition Limits (WT %)

| Silicon | 0.4 |

| Iron | 0.5 |

| Copper | 0.1 |

| Manganese | 0.20-0.70 |

| Magnesium | 3.5-4.5 |

| Chromium | 0.05-0.25 |

| Zinc | 0.25 |

| Titanium | 0.15 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum |

Typical Mechanical Properties

| Temper | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| KSI | KSI | % | |

| O (annealed) | 44 | 14 | 16 |

| H32 | 47 | 28 | 12 |

| H112 | 35 | 14 | 14 |

| H116 | 40 | 28 | 10 |