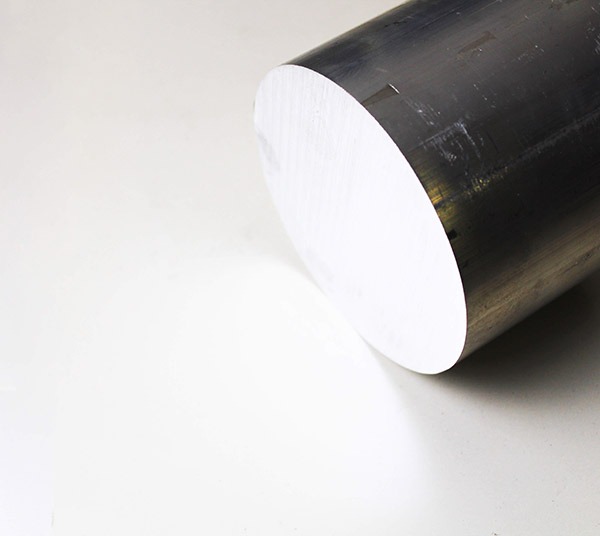

4340 ALLOY BAR

4340 ALLOY BAR

4340 alloy steel bar is used heavily in the aerospace industry due to its ultra-high strength. When heat treated it is known for its toughness while preserving good fatigue strength. For highly stressed parts it is excellent choice. It can be machined by all customary methods. This material is available in both vacuum melt (VM) and air melt (AM).

APPLICATIONS:

- Aircraft Landing Gear

- Power Transmission Gears

- Structural Use Applications

Typical Chemical Properties

| Minimum Properties | Tensile Strength , psi | 140,000 |

| Yield Strength, psi | 120,000 | |

| Elongation | 14% | |

| Hardness | Rc 32/39 | |

| Chemistry | Carbon( C) | .38 -.43% |

| Chrome (Cr) | 0.70- 0.90% | |

| Manganese (Mn) | 0.60-0.80% | |

| Molybdenum (Mo) | 0.20 – .30% | |

| Nickel ( Ni) | 1.65-2.0% | |

| Phosphorus (P) | 0.030% | |

| Sulphur (S) | 0.040% | |

| Silicon (Si) | 0.15- 0.35% |