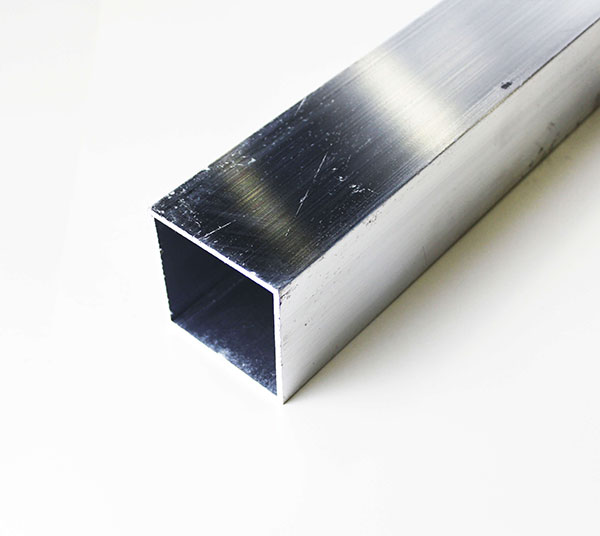

316 / 316L STAINLESS ORNAMENTAL TUBING

316 / 316L STAINLESS ORNAMENTAL TUBING

Part of the austenitic family of stainless steel, both 316 and 316L stainless ornamental tubing contain slightly more nickel than T304/304L, as well as 2-3% molybdenum. This allows for better corrosion resistance than T304, especially in environments that tend to cause pitting. It is widely used in the chemical processing industries.

STOCK SIZE RANGE:

Squares – 1/2″ OD – 6″ OD Wall Thickness – .065 – .180

Rectangles – 1/2″ x 1″ to 6″ Wall Thickness – .065 – .250

Rectangles – 1/2″ x 1″ to 6″ Wall Thickness – .065 – .250

Typical Chemical Composition % (Max Values, Unless Noted)

| Weight % | C | Mn | P | S | Si | Cr | Ni | Moly |

|---|---|---|---|---|---|---|---|---|

| 316 | 0.08 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| 316L | .035 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 10.0-15.0 | 2.0-3.0 |

Typical Mechanical Properties

| Grade | Tensile | ||||

|---|---|---|---|---|---|

| Ultimate/Min | Yield/Min | Elongation/Min | |||

| KSI | MPA | KSI | MPA | % | |

| 316 | 75 | 517 | 30 | 207 | 35 |

| 316L | 70 | 483 | 25 | 172 | 35 |