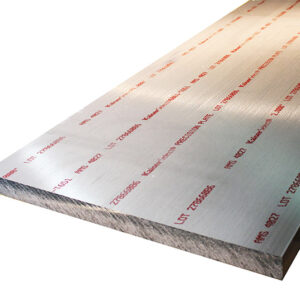

2024 ALUMINUM SHEET

2024 ALUMINUM SHEET

2024 aluminum coils and sheets are considered the “aircraft” alloy because of its strength. It is readily formed in the annealed condition and may be subsequently heat treated. 2024 aluminum sheets possess good machinability and can be machined to a high finish. Since corrosion resistance is relatively low, aluminum alloy 2024 is commonly used with an anodized finish or in clad form (“Alclad”) with a thin surface layer of high purity aluminum. As an enhanced sheet for fuselage applications, Alclad offers improved fracture toughness and fatigue crack growth while maintaining the strength characteristics of the alloy. 2024 aluminum is often used for applications in the aerospace industry.

APPLICATIONS

- Commercial and military fuselage skins

- Aircraft fittings

Chemical Composition Limits (WT%)

| Silicon | 0.5 |

| Iron | 0.5 |

| Copper | 3.8-4.9 |

| Manganese | 0.30-0.90 |

| Magnesium | 1.2-1.8 |

| Chromium | 0.1 |

| Zinc | 0.25 |

| Titanium | 0.15 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum | |

Typical Mechanical Properties

| Temper | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| KSI | KSI | % | |

| O (annealed) | 32 | 14 | 12 |

| T3 | 63 | 42 | 15 |

TW Metals stock a full product line ranging in thicknesses from .016 – .190 and in widths of 48″ and 60″. All are certified to ASTM B209 and both Bare and Alclad are certified to the appropriate AMS-QQ-A and AMS specifications.