2024 ALUMINUM AEROSPACE

2024 ALUMINUM AEROSPACE

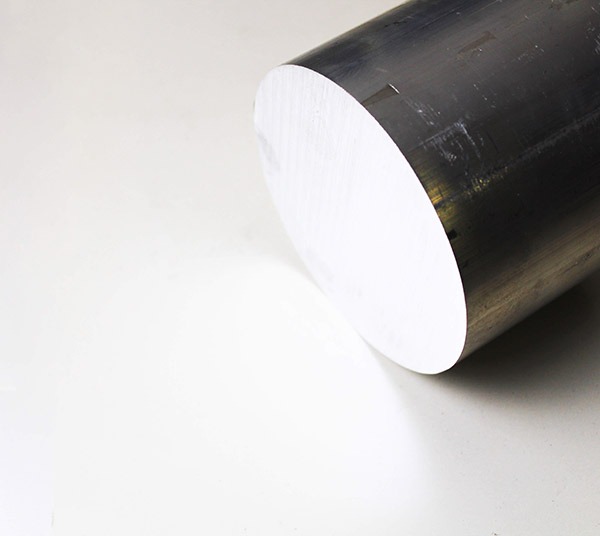

AL-2024 (UNSA902404) is an aerospace aluminum bar with cold finished or extruded aluminum wrought product providing high to moderate strength, very good machinability and weld ability with improved stress corrosion cracking resistance.

2024 is known as the “aircraft alloy” in machining rod. It is one of the most popular alloys for cold heading and roll threading applications. It has high strength and excellent fatigue resistance. It is excellent on parts where good strength –to-weight ratio is needed. Machinability is good in heat treated and annealed condition. Commonly used in aircraft structural components, truck wheels, medical instruments, and screw machine products. We stock 2024-T351, 2024-T3511, and 2024-T4.

Available shapes: Flats, squares and rounds

Tempers: T351, T3511 & T4

Specifications: ASTM B211, AMS 4120, AMS 4339, AMS-QQ-A-225/6, ASTM B221, AMS 4152, AMS 4164, AMS 4165, AMS-QQ-A-200/3

Typical Chemical Composition %

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | 3.80 | 1.20 | 0.30 | |||||||

| Maximum | 0.50 | 0.50 | 4.90 | 1.80 | 0.90 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 |

Remainder Aluminum

Typical Mechanical Properties

| Temper | Tensile | Hardness | ||||

|---|---|---|---|---|---|---|

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T4, T351 | 68 | 469 | 47 | 324 | 19 | 120 |