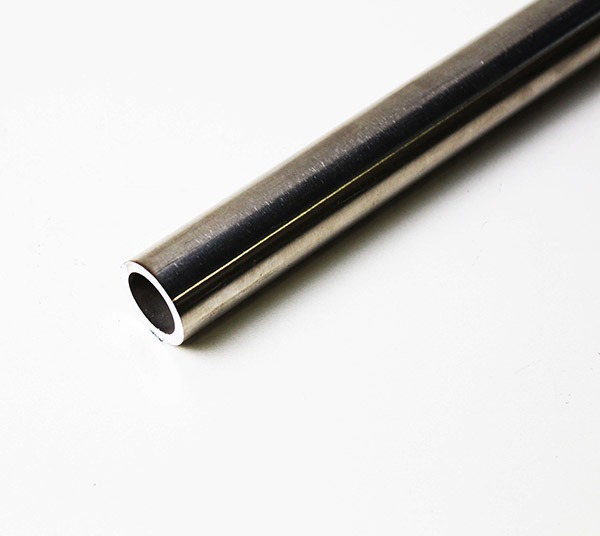

7075 ALUMINUM TUBING

7075 ALUMINUM TUBING

7075 drawn aluminum tubing is a zinc alloyed aluminum product heavily used in the aircraft / aerospace industry due to its superior strength. The T6 temper offers fair machinability, resistance welding and corrosion resistance. The T73 temper offers superior stress corrosion resistance.

DRAWN ALUMINUM TUBING PDF DOWNLOAD

7075 ALUMINUM TUBING STOCK SIZE RANGE:

OD:1/2″ through 3″

Walls: .035 through .250

Shapes: Rounds, squares and rectangles

Tempers: O, T6, T73

Specifications: ASTM B210, AMS-WWT-700/7

Typical Chemical Composition %

| Weight % | Si | Fe | Cu | Mn | Mg | CR | Zn | TI | Each | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | 1.20 | 2.10 | .18 | 5.10 | ||||||

| Maximum | .40 | .50 | 2.00 | .30 | 2.90 | .28 | 6.10 | .20 | .05 | .15 |

Remainder Aluminum

Typical Mechanical Properties

| Temper | Tensile | Hardness | ||||

|---|---|---|---|---|---|---|

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| O | 33 | 228 | 15 | 103 | 17 | 60 |

| T6 | 83 | 572 | 73 | 503 | 11 | 150 |

| T73 | 73 | 503 | 63 | 434 | 13 | |