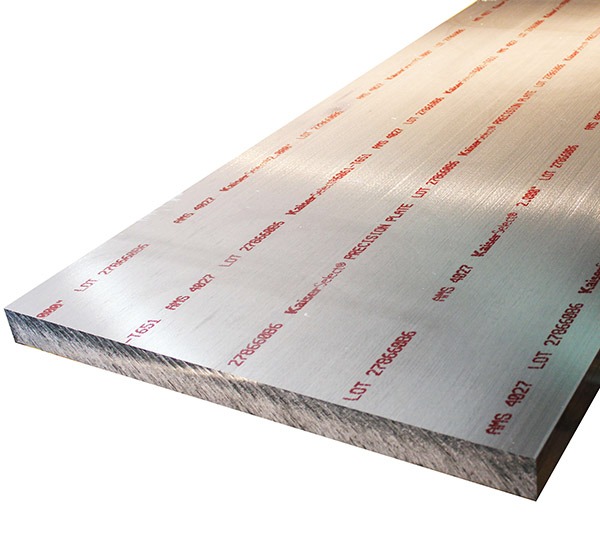

7075 ALUMINUM PLATE

7075 ALUMINUM PLATE

Alloy 7075 aluminum plates are the outstanding member of the 7xxx series and remains the baseline among the highest strength alloys available. Zinc is the primary alloying element giving it strength comparable to steel. Temper T651 possesses good fatigue strength, fair machinability, resistance welding and corrosion resistance ratings. Alloy 7075 in temper T7x51 has superior stress corrosion resistance and replaces the 2xxx alloy in the most critical applications. It is widely used by the aircraft industry with the typical specifications of ASTM B209, AMS-QQ-A-250/4, as well as many end users requirements.

APPLICATIONS:

- Air-frame structures

- Highly stressed aircraft parts

Chemical Composition Limits (WT %)

| Silicon | 0.4 |

| Iron | 0.5 |

| Copper | 1.2-2.0 |

| Manganese | 0.3 |

| Magnesium | 2.1-2.9 |

| Chromium | 0.18-0.28 |

| Zinc | 5.1-6.1 |

| Titanium | 0.2 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Balance, Aluminum |

Typical Mechanical Properties

| Thickness | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| In. | KSI | KSI | % |

| .250-4.00 | 83-73 | 73-63 | 13-11 |

typically available in T7351 TemperTW Metals stocks a full product line in tempers T651 and T7351 with widths 48.5″ and 60.5″. All are certified to ASTM B209, AMS-QQ-A-250/12 and AMS specifications, as well as other customer requirements.