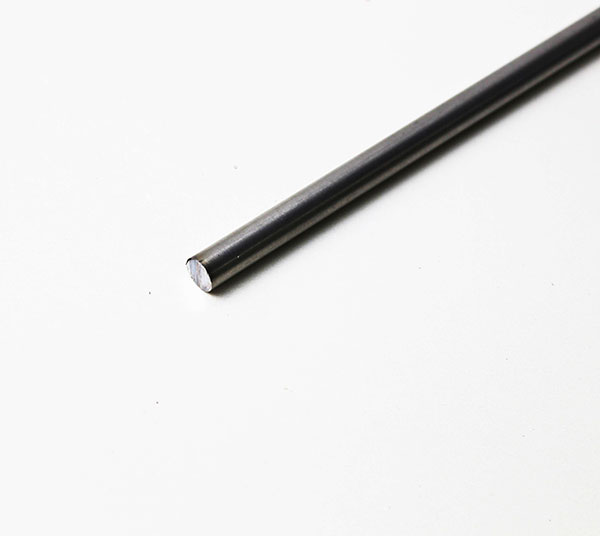

718 NICKEL BAR

718 NICKEL BAR

718 NICKEL BAR, WIRE, ROD

Alloy 718 is a precipitation-hardening nickel-chromium alloy containing significant amounts of iron, columbium, and molybdenum, along with lesser amounts of aluminum and titanium. It is sometimes referred to as a “super alloy”.

718 is commonly used in High temperature bolts, nuts and fasteners, Airframe parts, Gas turbine engines, Cryogenic tanks and Nuclear engineering applications

| Chemical Properties | ||

| Element | min | max |

| Carbon | — | 0.08 |

| Manganese | — | 0.35 |

| Silicon | — | 0.35 |

| Phosphorus | — | 0.015 |

| Sulfur | — | 0.015 |

| Chromium | 17 | 21 |

| Nickel | 50 | 55 |

| Molybdenum | 2.8 | 3.3 |

| Columbium (Niobium) | 4.75 | 5.5 |

| Titanium | 0.65 | 1.15 |

| Aluminum | 0.2 | 0.8 |

| Cobalt | — | 1 |

| Tantalum | — | 0.05 |

| Boron | — | 0.006 |

| Copper | — | 0.3 |

| Iron | remainder | |

| Tensile Properties | ||

| Solution Heat Treated | ||

| Tensile Strength, max | 155(KSI) | |

| Yield Strength at 0.2% Offset, max | 95 (KSI) | |

| Elongation in 2 Inches (50.8 mm), min | 30%ngth Super Alloy | |

Other Common Applications of 718

- Jet engine

- Gas turbine operations

- Base plates

- Rotor Bolts (Power Generation)