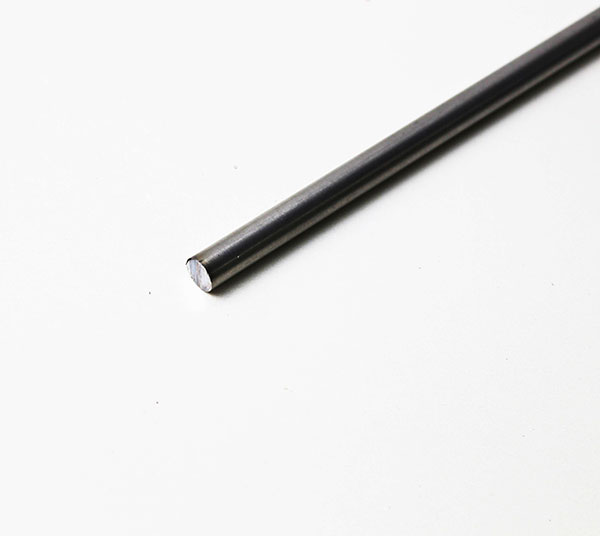

400 NICKEL BAR

400 NICKEL BAR

Nickel Alloy 400 bar, rod, and wire is a single-phase, solid-solution, nickel-copper alloy with excellent corrosion resistance to a wide range of media. Its unique composition provides a combination of the noble metal properties of copper as well as the passivation property of nickel.

BAR:

- ½” up to 4”

SHEET & PLATE:

- 1/8” up to ½”

PIPE:

- ½” up to 6” (40 & 80)

SPECIFICATIONS:

- UNS: NO4400

- W. Nr.: 2.436

- AMS: 4544

- ASME: SB 127

- ASTM: B 127

- Federal or Military: QQ-N-281

Chemical Composition %:

|

C |

Si |

Mn |

S |

Ni |

Cu |

Fe |

Al |

|

| MIN |

– |

– |

– |

– |

63.0 |

28.0 |

– |

– |

| MAX |

0.3 |

0.5 |

2.0 |

0.24 |

70.0 |

34.0 |

2.5 |

0.5 |

Features:

- Corrosion resistance in a wide range of marine and chemical environments

- Freedom from chloride-induced stress-corrosion cracking

- Good mechanical properties from sub-zero temperatures to approximately 550°C (1020°F)

- Approved for pressure vessels with wall temperatures up to 900°F (480°C) according to ASME Boiler and Pressure Vessel Code.

- Good workability and weldability

Applications

- Feed-water and steam-generator tubing in power plants

- Brine heaters and evaporator bodies in seawater desalination plants

- Sulfuric and hydroflouric acid alkylation plants

- Industrial heat exchangers

- Cladding for crude oil distillation columns

- Splash-zone sheathing in offshore structures

- Propeller and pump shafts for seawater service

- Plants for uranium and isotope separation in the production of nuclear fuel

- Pumps and valves used in the manufacture of chlorinated hydrocarbons

- Monoethanolamine (MEA) reboiler tubes

Corrosion Resistance

Alloy 400 has outstanding resistance to neutral and alkaline salts. It has been a standard material for salt plants for many years.

This alloy is one of the few metallic materials that can be used in contact with fluorine, hydrofluoric

acid, hydrogen fluorine, or other derivatives. Alloy 400 shows very high resistance to caustic alkalies. Behavior in seawater is also excellent, with improved resistance to cavitation corrosion compared to copper-based alloys. It can be used in contact with dilute solutions of mineral acids, such as sulphuric and hydrochloric acids, particularly if they are air-free. However, as the alloy contains no chromium, corrosion rates may increase significantly in oxidizing conditions.

While Alloy 400 can be considered immune to chloride-ion stress cracking, it can stress crack in the presence of mercury or in most aerated HF vapors. A stress-relieving heat treatment is applied in such cases.