7075 AEROSPACE ALUMINUM

7075 AEROSPACE ALUMINUM

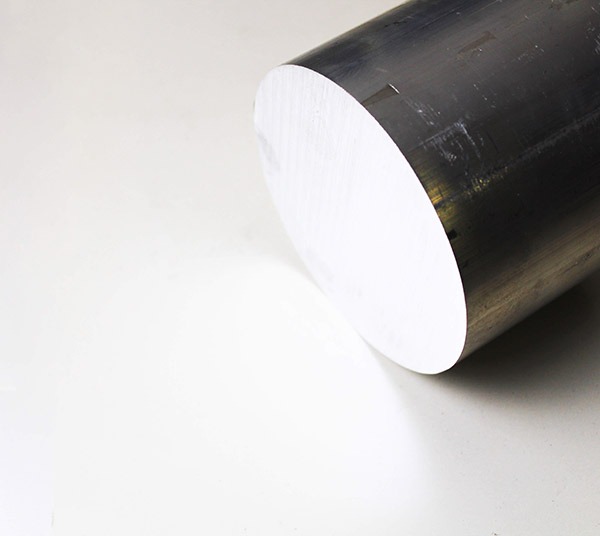

7075 (UNS A97075) is an aerospace aluminum bar with cold finished or extruded aluminum wrought alloy with high strength, adequate machinability and improved stress corrosion control. Fine grain control results in good tool wear.

7075 is one of the highest strength aluminum alloys. It has good fatigue strength and average machinability. Often used where parts are highly stressed. It is not weld able and has less corrosion resistance than other aluminum alloys. The mechanical properties depend on the temper of the material. Commonly used in the bicycle industry, aircraft structures, and in rifles for the American military. We stock 7075-T651, 7075-T6511, 7075-T7351, 7075-T3511 and 7075-T76511.

Available shapes: Flats, squares and rounds

Tempers: T6, T651, T73, T7351

Specifications: ASTM B211, AMS 4122, AMS 4123, AMS 4124, AMS4186, AMS-QQ-A-225/9, ASTM B221, AMS 4154, AMS 4166, AMS 4167, AMS-QQ-A-200/11

Typical Chemical Composition %

| Weight % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | 1.20 | 2.10 | 0.18 | 5.10 | ||||||

| Maximum | 0.40 | 0.50 | 2.00 | 0.30 | 2.90 | 0.28 | 6.10 | 0.20 | 0.05 | 0.15 |

Remainder Aluminum

Typical Mechanical Properties

| Temper | Tensile | Hardness | ||||

|---|---|---|---|---|---|---|

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T6, T651 | 83 | 572 | 73 | 503 | 11 | 150 |

| T73, T7351 | 73 | 503 | 63 | 434 | 13 | N/A |