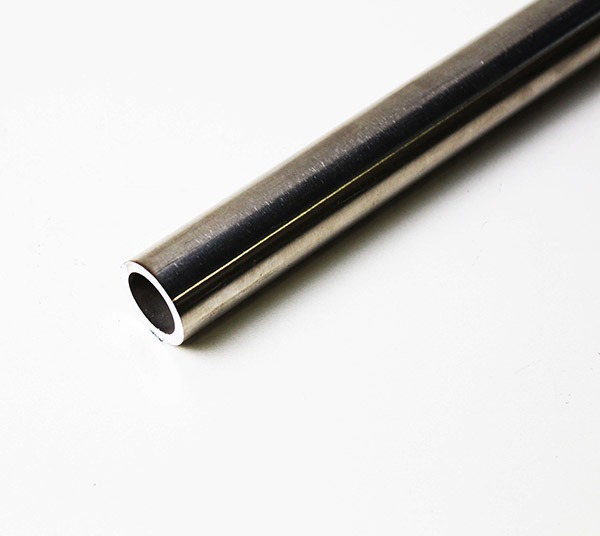

800 NICKEL PIPE

800 NICKEL PIPE

Alloy 800 nickel pipe is strong and resistant to oxidation and carburization at elevated temperatures. Resists sulfur attack, internal oxidation, scaling and corrosion in wide variety of atmospheres.

Typical applications include heat exchangers, process piping, carburizing fixtures and retorts, heating element sheathing, nuclear steam generator tubing and other components.

STOCK SIZE RANGE:

OD: 1/2″ through 6″

Wall: Schedule 40 through Schedule 80

Specifications: ASTM B407, ASME SB407

Typical Chemical Composition %

| Nickel | 30.0-35.0 |

| Iron | 39.5 min |

| Silicon | 1.0 max |

| Sulfur | 0.015 max |

| Carbon | 0.10 max |

| Manganese | 1.50 max |

| Copper | 0.75 max |

| Al | 0.15-0.60 |

| Cr | 19.0-23.0 |

| Ti | 0.15-0.60 |

Typical Mechanical Properties

| Annealed | 1000 psi |

| Yield Strength (0.2% offset) | 65 min psi |

| Tensile Strength | 25 min psi |

| Elongation % in 2 inches | 30 |